AI-Powered Multimodal Learning Bridges Scales in Materials Design

Published on Quantum Server Networks — October 2025

Artificial Intelligence has already transformed the landscape of materials science — enabling the rapid prediction of crystal structures, accelerating the discovery of high-entropy alloys, and driving innovations in polymers, nanomaterials, and semiconductors. But one of the most persistent challenges in AI-driven materials research is the multiscale and multimodal complexity of real materials. Their properties emerge from intricate relationships between composition, processing conditions, microstructure, and macroscopic performance — often across vastly different length and time scales.

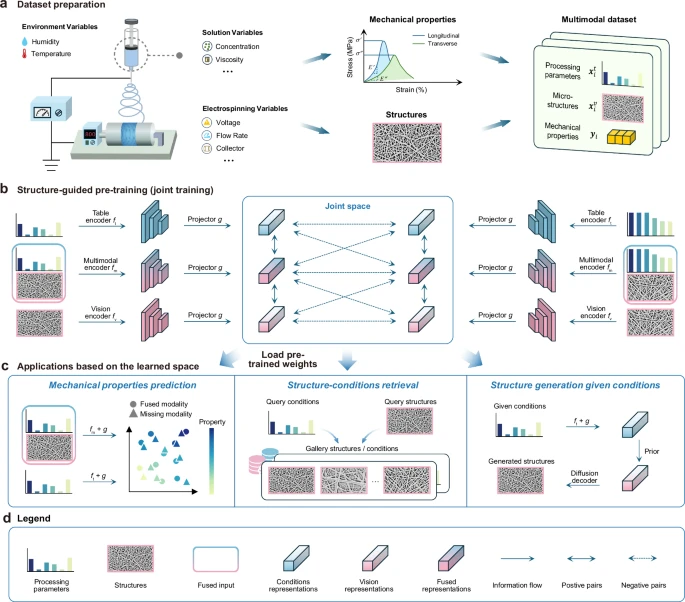

A groundbreaking new study published in npj Computational Materials by Wu et al. proposes a novel AI framework called MatMCL (Multimodal Contrastive Learning), designed to overcome these challenges by integrating multiple types of data (or “modalities”) even when some are missing. The article, titled “A versatile multimodal learning framework bridging multiscale knowledge for material design”, presents one of the most sophisticated approaches yet to bridge microstructure and processing information through AI.

Why Multimodal Learning Matters in Materials Science

Materials data are inherently heterogeneous: chemical compositions, processing parameters, microscopy images, spectroscopy, and mechanical measurements all provide different — but complementary — insights. Traditionally, machine learning models have relied on complete datasets for each material sample. However, in practice, many modalities are missing: for example, SEM or XRD data can be expensive and time-consuming to collect, leading to incomplete datasets and poor model performance.

Multimodal learning (MML) aims to integrate these diverse data types in a single learning framework. Recent advances in AI, such as CLIP and ImageBind, have shown how contrastive learning can align information from different domains. MatMCL builds on these ideas and adapts them specifically for materials science.

MatMCL: Bridging Scales with Structure-Guided Pretraining

The heart of MatMCL is a structure-guided pretraining (SGPT) strategy that uses multimodal contrastive learning to align processing data (such as flow rate, voltage, temperature, humidity, etc.) with microstructural data derived from SEM images. By projecting these different modalities into a shared latent space, MatMCL learns a unified representation that encodes multiscale correlations.

Crucially, once trained, the model can still make accurate predictions even if structural information is missing — a major advantage for virtual screening and data-scarce environments. In tests on electrospun nanofiber datasets, MatMCL achieved state-of-the-art performance for predicting five key mechanical properties (fracture strength, yield strength, elastic modulus, tangent modulus, and elongation), even without access to SEM data at inference time.

Beyond Prediction: Retrieval and Generation

MatMCL isn’t just a predictive tool. It also enables cross-modal retrieval — allowing researchers to find likely microstructures from processing conditions, or vice versa. This is particularly useful for navigating large materials databases.

Even more impressively, the authors developed a conditional structure generation pipeline inspired by generative diffusion models like DALL·E 2. Given a set of processing conditions, MatMCL can generate realistic microstructure images, with distributional statistics (orientation, fiber diameter, pore size) closely matching actual SEM data. This capability allows AI to “imagine” plausible material structures that have not yet been experimentally realized, potentially guiding future experimental synthesis.

Nanofiber Composites and Data Scarcity

To demonstrate real-world applicability, the team applied MatMCL to the design of nanofiber-reinforced composite materials — an area where datasets are typically extremely small. Using a multi-stage learning strategy, the model was first pretrained on nanofiber data, then fine-tuned on the limited composite dataset. This hierarchical transfer dramatically improved predictive accuracy compared to models trained from scratch, showing how pretraining on related tasks can bootstrap learning for scarce data scenarios.

Implications for AI-Driven Materials Discovery

The MatMCL framework represents a major step toward a new generation of AI systems that can seamlessly integrate multiscale, multimodal data in materials science. By handling missing data gracefully, enabling structure generation, and supporting cross-modal retrieval, it could form the backbone of future autonomous materials discovery platforms. Potential applications range from polymers and composites to crystalline solids, energy materials, and semiconductor design.

The full paper, including code and datasets, is available open-access: https://www.nature.com/articles/s41524-025-01767-3

This article was prepared with the assistance of AI technologies for content structuring and background research.

Sponsored by PWmat (Lonxun Quantum) – a leading developer of GPU-accelerated materials simulation software for cutting-edge quantum, energy, and semiconductor research. Learn more about our solutions at: https://www.pwmat.com/en

📘 Download our latest company brochure to explore our software features, capabilities, and success stories: PWmat PDF Brochure

🎁 Interested in trying our software? Fill out our quick online form to request a free trial and receive additional information tailored to your R&D needs: Request a Free Trial and Info

📞 Phone: +86 400-618-6006

📧 Email: support@pwmat.com

Comments

Post a Comment