AI-Driven Prediction Revolutionizes High-Entropy Alloy Discovery

Published in: npj Computational Materials (https://www.nature.com/articles/s41524-025-01811-2)

By researchers from Texas A&M University, Los Alamos National Laboratory, and the Max Planck Institute for Sustainable Materials

Reimagining Alloy Design Through Machine Learning

High-entropy alloys (HEAs) — materials composed of five or more principal elements in near-equal proportions — have captured global attention for their remarkable strength, ductility, and corrosion resistance. However, their vast compositional space poses a formidable challenge: experimentally characterizing every possible combination is nearly impossible. To accelerate discovery, scientists have increasingly turned to AI-driven surrogate modeling, capable of predicting material properties based on limited datasets.

A new study in npj Computational Materials now marks a milestone in this effort. The research team introduces a hybrid deep learning framework — a prior-guided Deep Gaussian Process (DGP) — that accurately predicts multiple mechanical and computational properties of HEAs, while also providing quantified uncertainty estimates. This is critical for data-sparse materials science, where each experiment can take weeks or months and cost thousands of euros.

The BIRDSHOT Dataset: A Treasure Trove for HEA Modeling

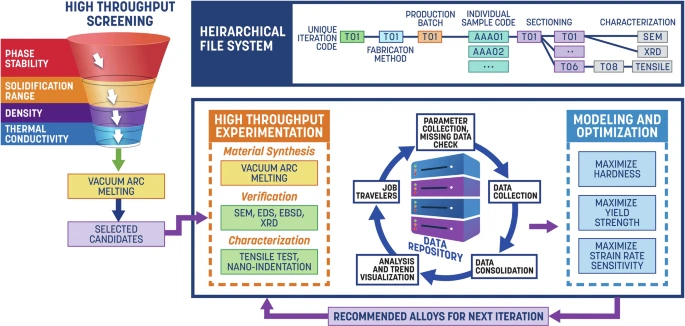

At the heart of this research lies the BIRDSHOT dataset — an extensive collection of over 100 precisely characterized HEA compositions within the Al-Co-Cr-Cu-Fe-Mn-Ni-V system. The dataset combines experimental data (yield strength, hardness, elongation, and modulus) with computationally derived features such as stacking fault energy (SFE), valence electron concentration (VEC), and simulated penetration depth. Each sample underwent rigorous synthesis via vacuum arc melting, microstructural analysis through EBSD and XRD, and advanced mechanical testing ranging from nanoindentation to split-Hopkinson bar impact.

Such detailed multimodal data enables cross-correlation between properties — for example, understanding how hardness and yield strength co-evolve with composition or how ductility depends on electronic structure. This level of integration is a cornerstone for future “self-driving” laboratories that learn in real time from experiments.

Deep Gaussian Processes: A Hierarchical AI Framework

Traditional Gaussian Processes (GPs) are popular in materials informatics for their ability to provide both predictions and confidence intervals. However, standard GPs assume uniform noise and struggle with incomplete or heterogeneous data — common in alloy research. The new Deep Gaussian Process (DGP) architecture extends this concept by stacking multiple GP layers, allowing it to model nonlinear and heteroscedastic relationships across multiple correlated outputs.

What makes this work stand out is the integration of a neural encoder-decoder model as a learned prior within the DGP. This hybrid approach effectively combines the expressive feature extraction of deep learning with the Bayesian uncertainty quantification of GPs. The resulting model, termed HDGP-P-All, outperformed all tested alternatives — including XGBoost, conventional GPs, and pure neural networks — in predicting key mechanical properties such as yield strength, ultimate tensile strength, and hardness.

AI Insights into Composition–Property Relationships

To interpret the predictions, the team employed SHapley Additive exPlanations (SHAP) analysis — an explainable-AI tool that quantifies how each element contributes to property changes. They found that aluminum (Al) and vanadium (V) had the strongest positive influence on mechanical strength, while chromium (Cr) and copper (Cu) tended to reduce strength but improve ductility. These trends are consistent with metallurgical theory, confirming that the AI model captures physically meaningful relationships.

Such interpretability is essential for trust in AI-guided materials design. By highlighting which elements most affect performance, these models can guide chemists and engineers in selecting optimal compositions before ever melting a sample.

Toward Autonomous Materials Discovery

The broader implication of this research is profound: autonomous alloy design powered by machine learning. When coupled with Bayesian optimization and robotic synthesis, uncertainty-aware DGPs can direct experiments toward the most promising candidates, dramatically reducing the number of trials required. In fact, the study reports achieving high-performance alloy predictions while exploring less than 0.2% of the feasible design space.

The authors emphasize that such models are not just predictive tools — they are decision engines for experimental design. By accurately ranking which alloy compositions are worth testing next, DGPs can shorten discovery cycles and minimize material waste, propelling the field toward fully integrated AI-driven “closed-loop” laboratories.

Looking Ahead

The success of prior-guided Deep Gaussian Processes opens new avenues in materials informatics, not only for HEAs but also for semiconductors, catalysts, and energy materials. Future directions include improving computational scalability, incorporating physics-based constraints, and coupling models with automated synthesis platforms. The study also plans to release the BIRDSHOT dataset publicly — a valuable benchmark for the entire materials-AI community.

As AI continues to merge with computational materials science, hybrid probabilistic frameworks like this represent the future of intelligent discovery — a future where uncertainty itself becomes a tool for innovation.

This article for Quantum Server Networks was prepared with the assistance of advanced AI technologies to ensure clarity, accuracy, and readability.

Sponsored by PWmat (Lonxun Quantum) – a leader in GPU-accelerated materials simulation software for quantum, energy, and semiconductor research. Learn more at www.pwmat.com.

📘 Download our latest company brochure: PWmat PDF Brochure

🎁 Try PWmat for free: Request a Free Trial

📞 +86 400-618-6006 | 📧 support@pwmat.com

© 2025 Quantum Server Networks | All Rights Reserved

#HighEntropyAlloys #MaterialsInformatics #DeepGaussianProcesses #MachineLearningMaterials #AIinMaterialsScience #NatureComputationalMaterials #BayesianOptimization #HEA #QuantumServerNetworks #PWmat #TexasAM #LosAlamosLab #AIforScience

Comments

Post a Comment