TETRA: Revolutionizing Materials Science with AI, Robotics, and Accelerated Testing

Scientists and engineers at the Johns Hopkins Applied Physics Laboratory (APL) in Laurel, Maryland, are reimagining how materials for the defense industrial base are designed, tested, and deployed. Their ambitious program, called Transforming Evaluation and Testing via Robotics and Acceleration (TETRA), combines artificial intelligence, robotics, and advanced manufacturing to radically accelerate the process of materials development.

The Challenge: Legacy and Next-Generation Materials

The U.S. Department of Defense faces a dual challenge: maintaining legacy metallic components while also introducing advanced alloys that push performance boundaries. Traditional approaches to alloy development and qualification are notoriously slow, expensive, and inefficient—sometimes taking months or years to validate a single material. According to APL’s Sal Nimer, this lag has hindered the ability to rapidly deploy next-generation materials where they are most needed.

The TETRA Paradigm Shift

At the heart of TETRA is a reimagined version of the materials science tetrahedron, a conceptual model linking processing, structure, properties, and performance. By introducing robotics and accelerated synthesis methods, APL is building a system capable of producing and testing materials at unprecedented speeds.

Instead of the traditional serial process—casting large ingots, machining test specimens, and evaluating each one independently—TETRA uses combinatorial synthesis and robotic testing to simultaneously explore hundreds of processing and compositional variants. This allows researchers to pinpoint optimal manufacturing pathways in days rather than months.

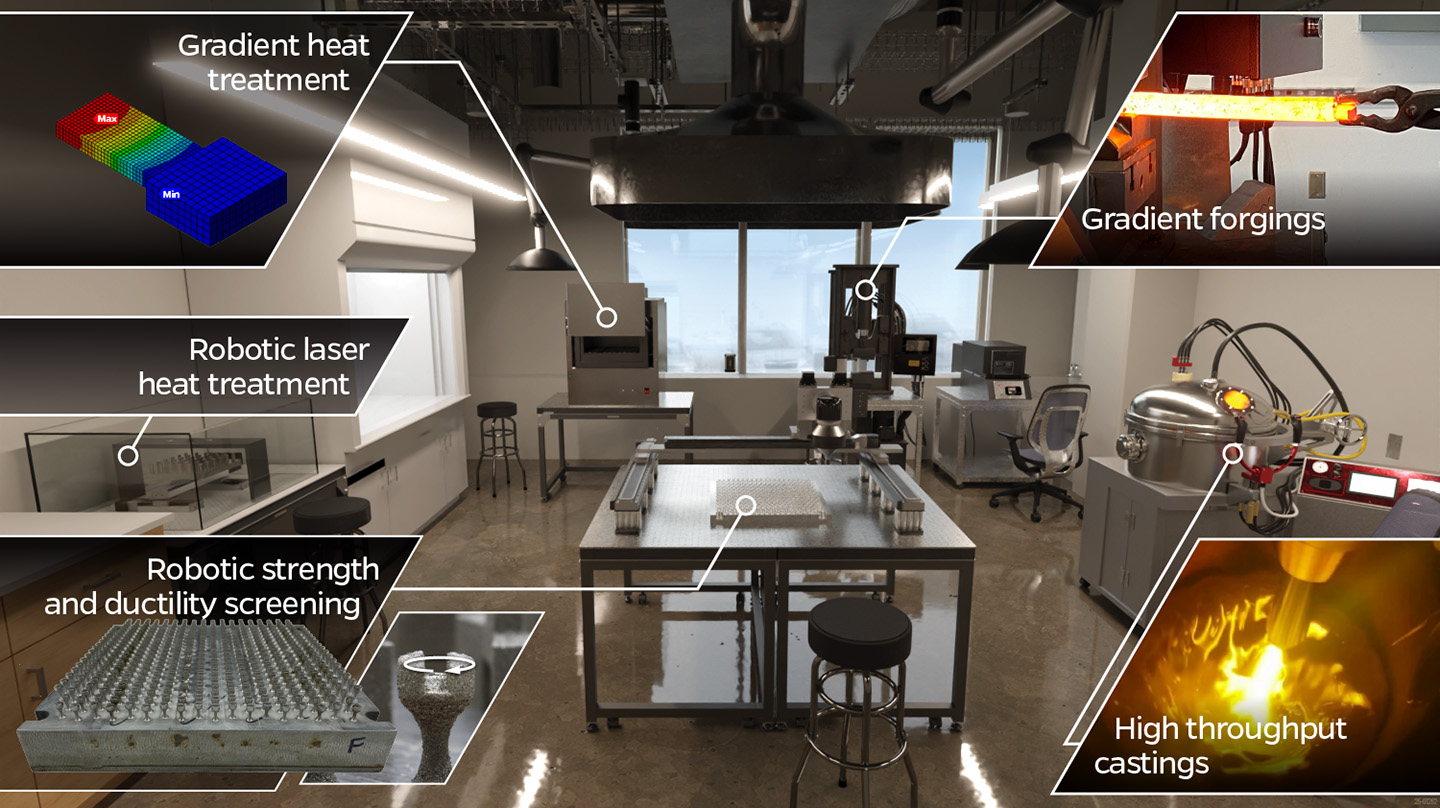

Advanced Manufacturing and Testing

One of TETRA’s most powerful tools is blown-powder directed energy deposition (DED), an additive manufacturing process where a laser melts metal powder layer by layer, creating dense, customizable samples. On a single build plate, researchers can print hundreds of alloys with varied chemical compositions, ready for automated mechanical testing.

Beyond additive manufacturing, the TETRA lab is equipped with ultrafast melting furnaces, heat treatment systems, forging equipment, and robotic gantries that can test mechanical properties across hundreds of samples in parallel. This integration makes TETRA a one-of-a-kind “all-in-one” R&D facility for alloy development.

From Defense Needs to Industrial Impact

The implications of TETRA extend beyond creating new alloys for extreme environments. By rapidly diagnosing why certain legacy parts fail during manufacturing, the system could improve quality assurance and reduce costly rejections. In the long term, its high-throughput testing capabilities will feed directly into AI-driven discovery pipelines, enabling autonomous labs where AI “co-engineers” suggest experiments, design alloys, and optimize performance with minimal human intervention.

The Future: AI as a Co-Investigator

TETRA is not just about speed—it’s about intelligence. APL envisions merging its accelerated materials development tools with AI algorithms that learn from experimental data and propose new research directions. This would effectively create AI-powered co-investigators, advancing us toward a future where self-running labs autonomously design and validate materials for critical applications.

As defense, aerospace, and energy industries seek stronger, lighter, and more resilient materials, the TETRA approach could redefine how innovation happens across the entire materials science landscape.

Read the full announcement here: Johns Hopkins APL – TETRA Mission-Critical Materials.

This article for Quantum Server Networks was prepared with the help of AI technologies to enhance clarity, readability, and SEO optimization.

Sponsored by PWmat (Lonxun Quantum) – innovators in GPU-accelerated materials simulation software for quantum, energy, and semiconductor research. Learn more at: www.pwmat.com

📘 Download their company brochure to explore features and success stories.

🎁 Try PWmat for Free: Request a trial version tailored to your R&D needs.

📞 Phone: +86 400-618-6006

📧 Email: support@pwmat.com

#TETRA #MaterialsScience #AIinScience #Robotics #AdditiveManufacturing #CombinatorialSynthesis #DefenseTechnology #AdvancedMaterials #JohnsHopkinsAPL #QuantumServerNetworks

Comments

Post a Comment