MIT’s Breakthrough: Real-Time 3D Monitoring of Corrosion and Cracking in Nuclear Reactors

Nuclear energy remains one of the most promising pathways for delivering large-scale, carbon-free electricity and powering naval propulsion systems. Yet one of its biggest challenges has always been the durability of reactor materials. Over time, radiation, heat, and corrosive environments compromise the structural integrity of reactor components. Now, researchers at MIT have pioneered a new technique that could revolutionize how engineers understand—and ultimately prevent—material failure inside nuclear reactors.

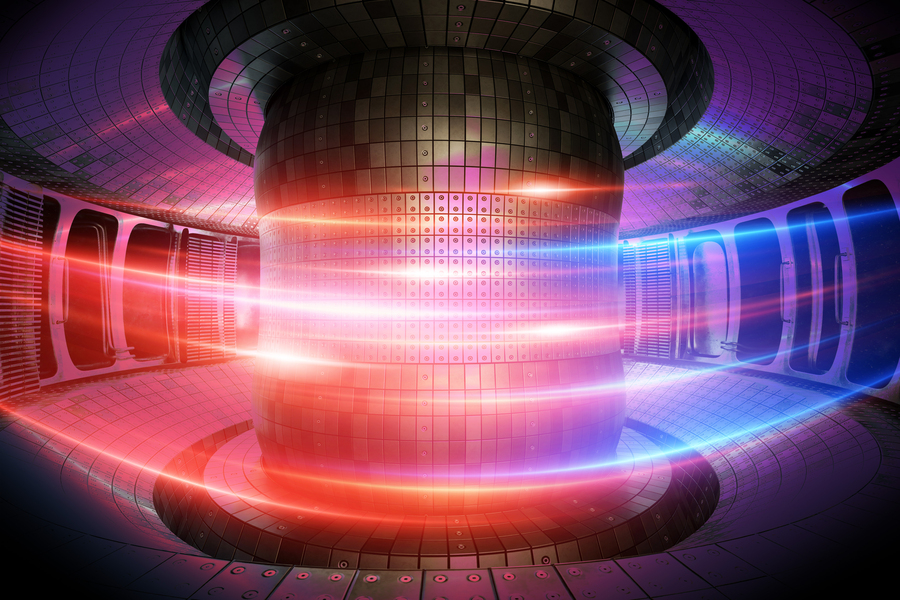

Image Credit: MIT News

A New Window into Material Failure

Traditionally, scientists have only been able to study nuclear reactor materials after the fact—removing components from their environments and then examining them with high-resolution imaging. This delayed approach makes it difficult to capture how failure mechanisms actually unfold. The new MIT technique, however, enables real-time, 3D monitoring of corrosion and cracking as it happens, offering unprecedented insight into the degradation process of reactor materials (MIT News).

How the Technique Works

To simulate the extreme environment inside a reactor, researchers used high-intensity X-rays to mimic neutron bombardment. By combining advanced X-ray probes with a buffer layer of silicon dioxide, they were able to stabilize nickel crystal samples long enough to watch them degrade under stress in real-time.

Key to this success was the use of phase retrieval algorithms, which reconstructed the 3D shape and strain state of the material as it failed. This allowed researchers to capture nanoscale processes of corrosion and crack propagation—critical information for designing next-generation nuclear materials.

Why This Matters for Nuclear Energy

The ability to visualize how materials fail in situ could extend the operational lifespan of nuclear reactors, making them safer, more efficient, and more sustainable. With nuclear energy expected to play a vital role in reducing carbon emissions, these insights come at a critical time. The new method may help prevent catastrophic failures, reduce downtime, and optimize materials used in advanced reactors.

Unexpected Benefits: Strain Control for Microelectronics

In addition to nuclear applications, the researchers discovered a surprising side benefit: the X-ray beam itself could be used to tune strain within a material. This has major implications for the microelectronics industry, where strain engineering is often employed to enhance a material’s electronic or optical properties. In effect, this breakthrough could serve both the nuclear energy sector and the semiconductor industry—two critical pillars of modern technology.

Future Directions

Looking ahead, the MIT team plans to apply their method to more complex alloys, such as steels used in both nuclear and aerospace engineering. They also want to refine the technique to explore how varying buffer layer thickness affects strain relaxation. Such work could lead to improved reactor safety, longer-lasting aerospace materials, and even new approaches to quantum materials research.

This breakthrough not only provides fundamental insight into how nanoscale materials respond to radiation but also demonstrates the profound impact of substrate engineering on strain relaxation. By marrying nuclear science with advanced imaging and computational tools, MIT researchers have pushed the boundaries of what’s possible in materials science, energy, and beyond.

🔗 Original article on MIT News: New method could monitor corrosion and cracking in nuclear reactor materials

This article on Quantum Server Networks was prepared with the assistance of AI technologies.

Sponsored by PWmat (Lonxun Quantum) – advancing GPU-accelerated materials simulation software for quantum research, energy technologies, and semiconductor innovation. Learn more at: www.pwmat.com/en

📘 Explore our latest company brochure with detailed case studies and technical insights: PWmat PDF Brochure

🎁 Try PWmat for free: Request a demo tailored to your R&D projects: Request Free Trial

📞 Phone: +86 400-618-6006

📧 Email: support@pwmat.com

#NuclearEnergy #MaterialsScience #Corrosion #MITResearch #Nanotechnology #GreenTech #EnergyInnovation #QuantumServerNetworks #Microelectronics #StrainEngineering

Comments

Post a Comment