Beaded Metamaterials: From Ancient Craft to Future-Ready Engineering

Mechanical metamaterials have rapidly become one of the most exciting fields in advanced materials science. Defined by their ability to derive unique properties from structure rather than composition, metamaterials have already led to breakthroughs in optics, acoustics, and mechanics. A new study published in Nature Communications (read the article here) explores a surprising twist on this theme: the transformation of traditional beadwork into programmable, load-bearing beaded metamaterials.

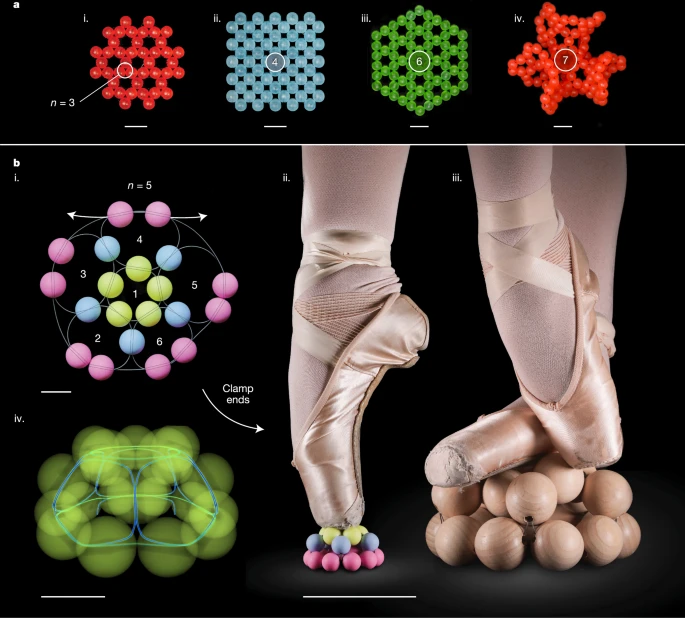

Image: Experimental design of beaded metamaterials (Nature Communications, 2025)

From Soft Fibers to Rigid Structures

The study, led by researchers from Princeton University, Boston University, Carnegie Mellon, and KU Leuven, investigates how rigid beads connected by flexible threads can form networks that dramatically alter their mechanical response. By weaving beads into specific patterns and applying tension, these flexible textiles can “lock” into rigid, load-bearing configurations—a phenomenon the authors call superjamming.

In simple terms, softness and compliance give way to rigidity once the beads and threads reach a critical arrangement. Remarkably, small-scale bead-thread shells were shown to withstand forces strong enough to support the weight of a human adult. This ability to switch between flexibility and stiffness echoes natural systems such as tendons and woven biological tissues, while offering new routes for human-engineered materials.

The Physics Behind Superjamming

The research demonstrates that the mechanics of bead-thread networks are governed not only by the material of the thread (nylon vs. nitinol) but also by friction, geometric frustration, and slack. By carefully adjusting tension and weaving geometry, researchers can induce stable rigid states that resist deformation far beyond the capacity of individual fibers or beads alone.

This hybrid behavior resembles granular jamming—seen in sand piles or packed grains—but with the added advantage of programmability. Unlike random granular systems, beaded metamaterials allow engineers to design specific responses by controlling how threads interconnect the beads.

Applications on the Horizon

The implications of these findings extend across multiple sectors:

- Wearable technology – Flexible yet rigid-on-demand fabrics could lead to adaptive clothing, protective gear, or medical exoskeletons.

- Architecture and construction – Large-scale beaded networks might form lightweight, deployable structures such as roofs, shelters, or space habitats.

- Soft robotics – Robots with tunable stiffness could handle delicate objects one moment and perform heavy-duty tasks the next.

- Energy absorption systems – Superjammed configurations could enhance shock absorbers or protective barriers, useful in both automotive and aerospace applications.

What makes this research particularly exciting is how it bridges the gap between ancient craft and modern science. Bead weaving, a practice found in countless cultures worldwide, is reimagined as a high-tech strategy for building the next generation of mechanical metamaterials.

A Paradigm Shift in Material Design

Beaded metamaterials embody a broader trend in materials science: moving away from brute-force reliance on chemical composition and instead harnessing geometry, topology, and nonlinear mechanics to achieve desired properties. As noted in the study, combinations of friction, slack, and geometric frustration provide unprecedented tunability. This dual nature—soft yet strong, flexible yet rigid—positions beaded metamaterials as a promising platform for future engineering innovations.

In the longer term, combining beaded architectures with stimuli-responsive threads (such as shape-memory alloys or smart polymers) could enable self-adjusting, reconfigurable materials. Imagine a structure that stiffens automatically in response to heat, light, or mechanical stress—adaptive matter that learns and responds to its environment.

Conclusion

This groundbreaking study offers more than just a novel take on beadwork—it provides a conceptual framework for designing programmable, load-bearing metamaterials. By leveraging age-old textile techniques, scientists have unlocked new pathways toward materials that are lightweight, reconfigurable, and mechanically robust.

The next frontier in metamaterials may not come solely from futuristic nanofabrication labs, but also from a re-examination of traditional crafts through the lens of modern physics.

Footnote: This article was prepared with the assistance of AI technologies to support research communication and science outreach.

Sponsored by PWmat (Lonxun Quantum) – a leading developer of GPU-accelerated materials simulation software for cutting-edge quantum, energy, and semiconductor research. Learn more about our solutions at: https://www.pwmat.com/en

📘 Explore our capabilities in advanced materials simulation: Download the PWmat Company Brochure

🎁 Try PWmat software today! Request a free trial and get additional technical information tailored to your R&D needs: Free Trial Request Form

📞 Phone: +86 400-618-6006

📧 Email: support@pwmat.com

#BeadedMetamaterials #MechanicalMetamaterials #MaterialsScience #QuantumServerNetworks #SoftRobotics #AdaptiveMaterials #Superjamming #Nanotechnology #FutureMaterials #PWmat

Comments

Post a Comment