3D Printing in Orbit: The Future of Space Structures with Fiber-Reinforced Composites

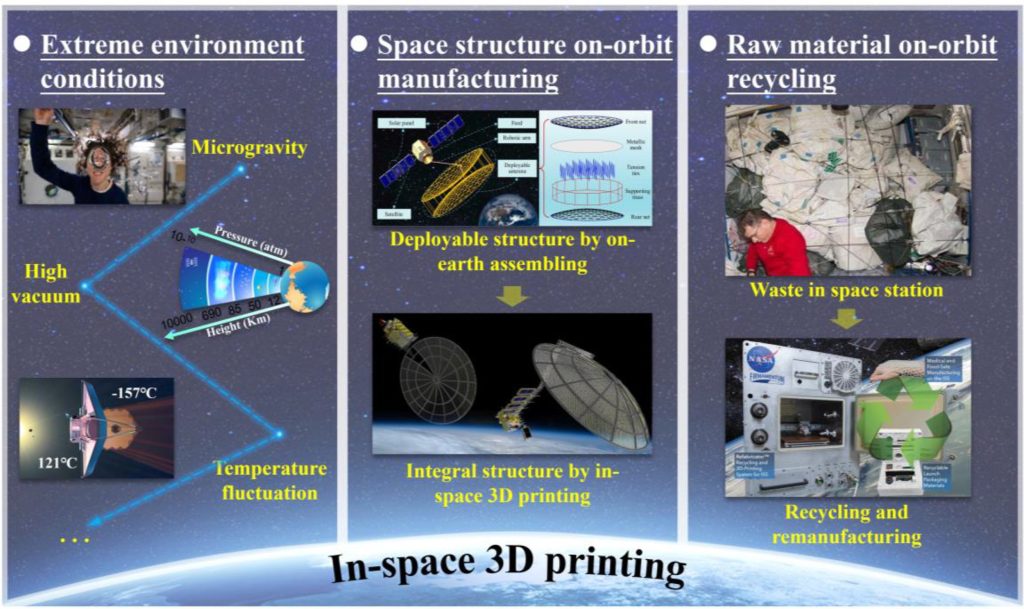

In-space manufacturing is moving from science fiction to operational reality. A comprehensive review published on ScienceDirect by researchers from Xi’an Jiaotong University and the China Academy of Space Technology outlines how additive manufacturing (AM)—specifically using polymers and fiber-reinforced composites—can transform space exploration and satellite construction. This new approach offers a way to bypass the extreme cost and size limitations imposed by Earth-based manufacturing and launch logistics.

Traditionally, all space structures are fabricated on Earth and launched into orbit, incurring costs of over $10,000 per kilogram. Design constraints are dictated by the payload fairing size, and excessive redundancy is often needed to survive the stresses of launch. In contrast, 3D printing directly in space enables lightweight, structurally optimized designs to be produced on-demand in orbit—dramatically reducing waste, costs, and logistical complexity.

Why Polymers and Composites?

Thermoplastic polymers—especially fiber-reinforced variants—offer low processing temperatures, high strength-to-weight ratios, radiation resistance, and recyclability. Materials like ABS, Ultem 9085, PEKK, PEI, and carbon fiber-reinforced PEEK have already been successfully tested in microgravity environments, showing negligible mechanical degradation compared to Earth-based prints.

NASA’s early trials began in 1999 with ABS extrusion on parabolic flights. By 2014, Made In Space Inc. printed the first functional tools aboard the International Space Station (ISS). Over 200 parts have since been fabricated in orbit, including brackets, medical tools, and housing components.

Engineering Challenges: Printing in Microgravity and Vacuum

Printing in space isn’t simply a matter of installing a 3D printer on a spacecraft. In microgravity, the absence of hydrostatic pressure changes material flow—surface tension becomes dominant, increasing the risk of spherical bead formation. Precision in nozzle-substrate distance is crucial for filament continuity.

In vacuum conditions, the absence of convection cooling shifts heat transfer to conduction and radiation, slowing cooling rates and altering layer bonding. Specialized vacuum-compatible hotends, such as those developed at Virginia Tech, use titanium heat breaks and radiative heat sinks to maintain stable extrusion temperatures.

Performance in Extreme Conditions

Tests have shown remarkable results: PEEK components printed in vacuum at 100 Pa exhibited a 212.5% increase in tensile strength along certain orientations compared to atmospheric prints. However, some fiber-reinforced composites displayed reduced strength due to porosity formation. Outgassing—a critical safety factor for spacecraft interiors—has been measured for various polymers, with PEKK and PEI showing excellent compliance with NASA’s stringent thresholds.

Applications in Space Structures

- Debris Shielding: Variable-density lattice shields printed from Ultem have absorbed high-speed impacts from 4 mm aluminum projectiles at over 5 km/s.

- Truss Frameworks: Systems like SpiderFab and Redwire’s OSAM have fabricated lightweight, meter-scale trusses in orbit using composite extrusion methods.

- Recycling Systems: The ISS-deployed Refabricator recycles Ultem 9085 into new filament, enabling closed-loop manufacturing for long-duration missions.

Composite Recycling in Orbit

Researchers have demonstrated reverse melting processes in vacuum to separate fibers from composite resin and re-draw them into usable filaments. In one case, remanufactured carbon fiber/PEEK composites displayed a tensile strength of 233.8 MPa—slightly higher than the original material—due to improved fiber wetting and reduced voids.

The Road Ahead

The review identifies several areas for further research, including:

- Simulating complex space environmental conditions for testing.

- Designing structures specifically for microgravity stiffness and load constraints.

- Autonomous robotic assembly of large-scale orbital structures.

- Integrating multiple materials into multifunctional space components.

As humanity pushes toward lunar bases, Mars expeditions, and megastructures in orbit, in-space 3D printing with advanced composites may become the backbone of space infrastructure—building everything from radiation shields to giant solar arrays without ever returning to Earth for resupply.

Read the original article here: 3D Printing Industry – Advanced In-Space 3D Printing of Composites for Orbit Use

Sponsored by PWmat (Lonxun Quantum) – a leading developer of GPU-accelerated materials simulation software for cutting-edge quantum, energy, and semiconductor research. Learn more about our solutions at: https://www.pwmat.com/en

📘 Download our latest company brochure to explore our software features, capabilities, and success stories: PWmat PDF Brochure

🎁 Interested in trying our software? Fill out our quick online form to request a free trial and receive additional information tailored to your R&D needs: Request a Free Trial and Info

📞 Phone: +86 400-618-6006

📧 Email: support@pwmat.com

Hashtags: #InSpaceManufacturing #3DPrinting #AdditiveManufacturing #FiberReinforcedComposites #SpaceTechnology #OrbitalConstruction #MicrogravityResearch #MaterialsScience #SpaceExploration #CompositeRecycling

Comments

Post a Comment