ITER’s Boronization System: Preparing the Tungsten Wall for Fusion’s Next Frontier

In a monumental step for fusion research, engineers and scientists at ITER are advancing the design of a boronization system to condition the plasma-facing walls of the tokamak. As ITER prepares to switch from beryllium to tungsten armour tiles in its plasma chamber, this new system is essential for mitigating impurities and ensuring efficient plasma performance.

Why Boronization Matters

Boronization involves coating plasma-facing surfaces with an ultra-thin layer of boron (10–100 nanometers) to capture oxygen impurities that can increase radiative losses. This is especially critical during the discharge-initiation phase, when plasma stability is most sensitive. ITER’s boronization system represents the largest-scale application of this proven technology, adapted for a tritiated environment never attempted before.

The System in Detail

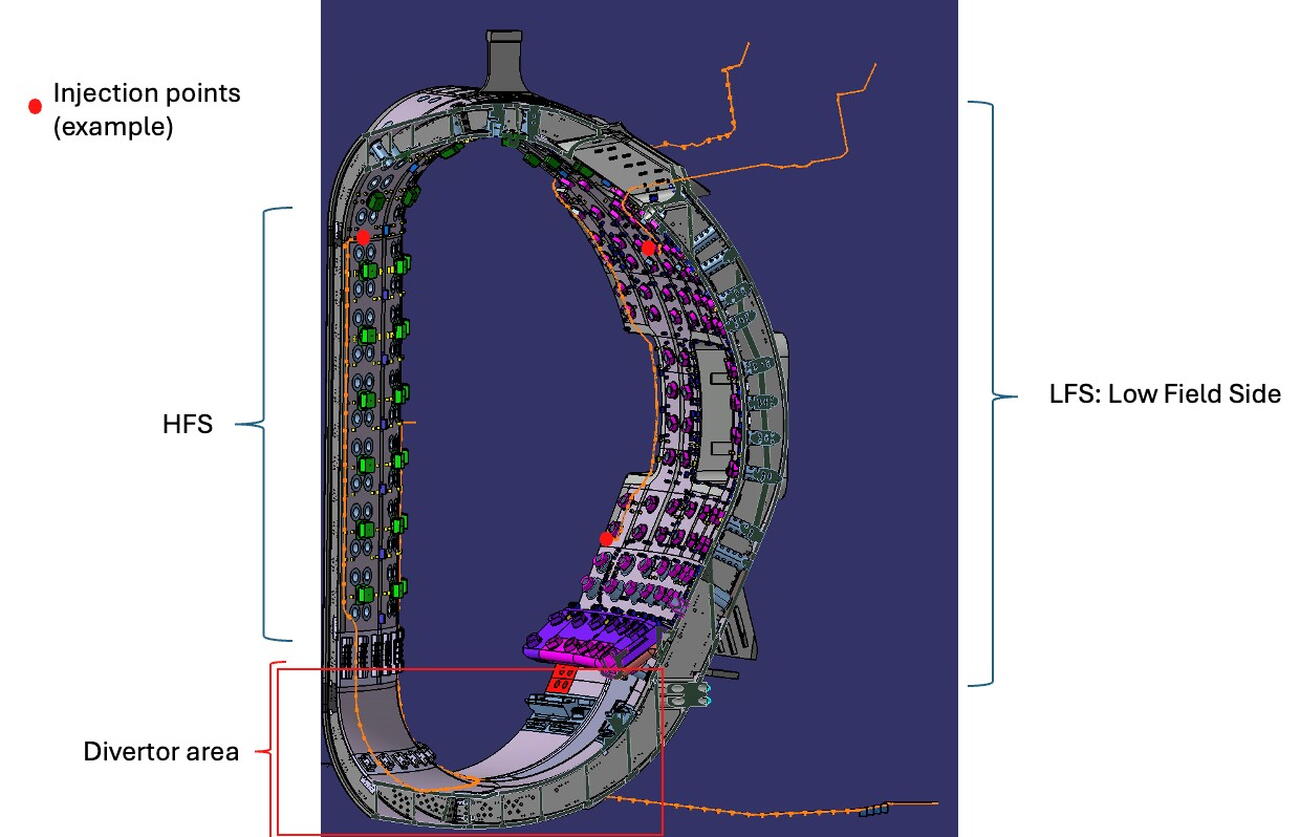

The process uses diborane (B2H6) mixed with helium as a carrier gas, delivered via a vast network of over one kilometre of gas injection lines. Inside the tokamak, 21 injection points evenly distribute the diborane for uniform wall coverage. Glow-discharge-assisted layer deposition is then employed to bond boron chemically to the tungsten surfaces.

Glow discharge, akin to a neon light, creates a cold plasma that accelerates ions towards the walls, enabling precise boron deposition. However, ITER’s higher-energy anodes and large-scale environment present unique challenges, which are being addressed with international collaboration and modeling.

Safety and Innovation

Due to diborane’s toxicity and explosiveness, a secure storage “gas cabin” is under design, alongside a thermal or chemical neutralization system for safely handling exhaust gases. These safeguards, combined with the optimized placement of anodes for even boron coverage, ensure the process integrates seamlessly with ITER’s complex systems.

“We’re working with a proven technology, but it’s never been done on this scale or in a tritiated environment, so it’s interesting territory.”

— Tom Keenan, Wall Conditioning Engineer, ITER

Read the original article here: https://www.iter.org/node/20687/boronization-system-takes-shape-iter-prepares-tungsten-wall

Sponsored by PWmat (Lonxun Quantum) – a leading developer of GPU-accelerated materials simulation software for cutting-edge quantum, energy, and semiconductor research. Learn more about our solutions at: https://www.pwmat.com/en

📘 Download our latest company brochure to explore our software features, capabilities, and success stories: PWmat PDF Brochure

📞 Phone: +86 400-618-6006

📧 Email: support@pwmat.com

#ITER #FusionEnergy #Boronization #PlasmaPhysics #MaterialsScience #QuantumServerNetworks #TungstenWall #PWmat

Comments

Post a Comment