Forged in Fire: ITER's Divertor Redefines Heat Tolerance in Fusion Reactors

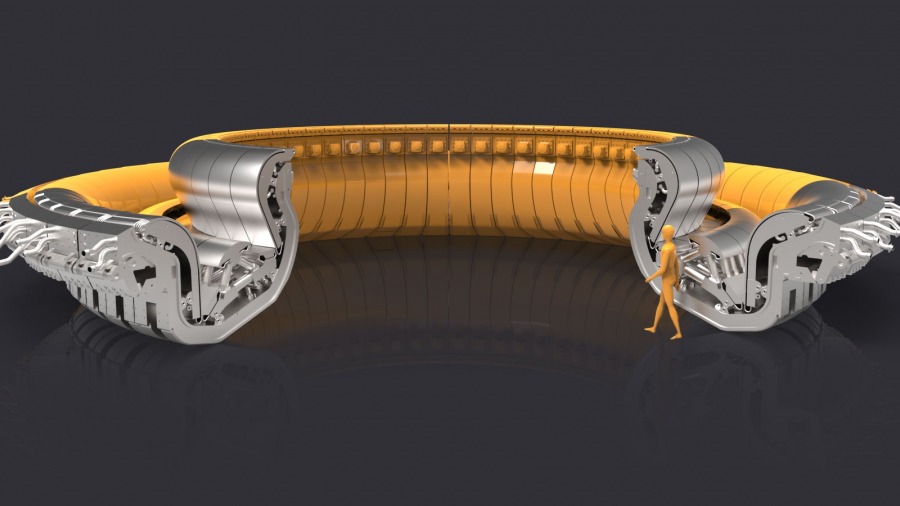

In a technological milestone that borders on science fiction, a critical component of the world’s largest fusion energy project—the ITER divertor—has successfully passed certification tests, proving capable of withstanding temperatures hotter than an asteroid impact. Developed through a joint effort by Hitachi and Japan’s National Institutes for Quantum Science and Technology (QST), this outer vertical target of the divertor plays a pivotal role in containing and stabilizing the blazing-hot plasma within the ITER tokamak, currently under construction in Southern France.

The Crucial Role of the Divertor

Often called the "exhaust system" of a fusion reactor, the divertor is the only component that comes into direct contact with the ultra-hot plasma. Its role is to remove byproducts such as helium ash and fuel residue, ensuring the sustained and stable operation of the fusion reaction. But unlike ordinary exhaust systems, this one must operate in conditions that push the boundaries of known materials science. How extreme? Try 20 megawatts per square meter—equivalent to 36,000°F (around 20,000°C)—along with electromagnetic forces reaching 33,000 pounds of pressure.

Extreme Materials for an Extreme Environment

Withstanding these brutal conditions required an ingenious blend of materials and engineering. The divertor's surface is constructed from welded tungsten monoblocks, one of the few materials capable of maintaining structural integrity at such heat levels. Beneath that lies a network of high-strength copper alloy cooling pipes engineered to retain thermal conductivity while under relentless stress.

The key innovation? A high-heat-resistant brazing technology that allows these radically different materials to be bonded without failure, even under thermal expansion and contraction cycles that would shatter most conventional joints.

Precision Manufacturing Meets Nuclear Demands

Hitachi’s contribution was no less critical. Responsible for the manufacturing process, they implemented robotic welding systems, non-destructive inspections, and machining tolerances tighter than 0.02 inches. This fusion of automation and craftsmanship ensured that each component meets the ITER Organization’s strict requirements, pushing industrial capabilities to their very limits.

Impact on the Future of Fusion and Beyond

The successful validation of the divertor prototype signals a major leap for the ITER Project, which aims to demonstrate the scientific and technological feasibility of nuclear fusion on a commercial scale. Beyond ITER, the materials and engineering principles refined in this project could serve other fusion projects globally—paving the way toward a cleaner, virtually limitless source of energy.

QST is already applying these insights to develop prototype reactors of their own, and the consortium is investigating other enhancements, such as boronization, which improves plasma performance by minimizing impurities. Each success brings us closer to energy that mimics the sun itself—clean, safe, and abundant.

Fusion Energy: Hype or the Next Horizon?

Fusion energy remains a tantalizing goal: a process that generates no greenhouse gases, creates negligible radioactive waste, and relies on fuel sources like deuterium found in seawater. The only catch? It’s unbelievably hard to control. The development of ultra-resilient components like the ITER divertor represents not just progress, but proof that humanity is inching closer to harnessing star power here on Earth.

The full article can be accessed at Sustainability Times.

Sponsored by PWmat (Lonxun Quantum) – a leading developer of GPU-accelerated materials simulation software for cutting-edge quantum, energy, and semiconductor research. Learn more about our solutions at: https://www.pwmat.com/en

📘 Download our latest company brochure to explore our software features, capabilities, and success stories: PWmat PDF Brochure

📞 Phone: +86 400-618-6006

📧 Email: support@pwmat.com

Comments

Post a Comment