Unlocking the Secrets of Greener Cement: Nanocrystalline Modeling of Calcium Aluminate Silicate Hydrate

The global push toward more sustainable infrastructure demands urgent innovation in cement technology. Cement, while indispensable, accounts for nearly 8% of global CO2 emissions. In this context, calcium aluminate silicate hydrate (C-A-S-H) — a critical component in low-carbon cement alternatives — emerges as a potential game-changer. But its complex nanostructure has long eluded comprehensive understanding. A new study, published in Nature Communications, sheds remarkable light on the atomistic behavior of C-A-S-H, offering key insights that could accelerate the development of durable and environmentally friendly cementitious materials.

Modeling Materials at the Atomic Scale

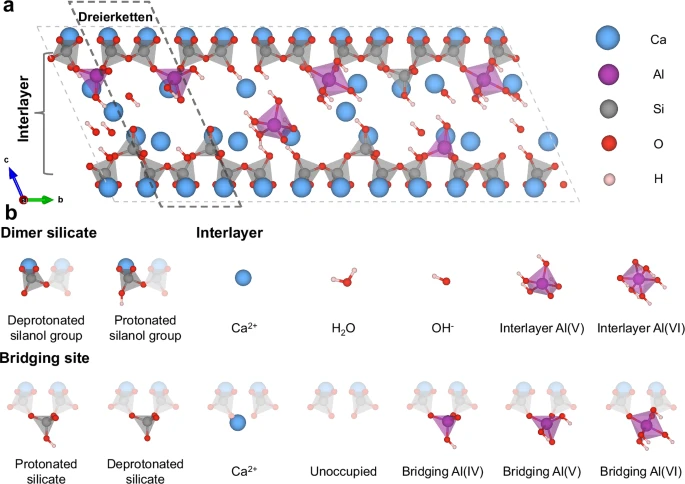

Led by Yunjian Li and colleagues from Macau University of Science and Technology, the team developed a powerful structure generation software tool called CASHgen. This tool enabled the high-throughput simulation of over 1600 distinct C-A-S-H nanostructures, systematically exploring the effects of varying calcium-to-silicon (Ca/Si) and aluminum-to-silicon (Al/Si) ratios. These structural models were refined using molecular dynamics simulations and validated against experimental data to yield reliable insights into key properties like mean chain length (MCL), interlayer spacing, density, and elastic modulus.

Key Discoveries: The Composition-Structure-Property Nexus

One standout result from the study is that C-A-S-H achieves optimal mechanical performance at a Ca/Si ratio near 1.5. Deviating from this sweet spot introduces structural disorder, reducing stiffness and packing density. On the other hand, higher Al/Si ratios enhance the polymerization of silicate chains, increasing the MCL and leading to improved mechanical robustness. These atomic-scale observations directly inform strategies for formulating more durable and eco-friendly cement mixtures.

The researchers also discovered that interlayer calcium ions significantly affect the material’s stiffness along the vertical (Z) axis. High interlayer Ca density was shown to stabilize the material’s elastic modulus, indicating a critical threshold beyond which additional Ca provides diminishing returns. Conversely, aluminum incorporation strengthens horizontal bonds (X and Y axes), particularly by occupying bridging sites and forming Al–O–Si linkages.

Why This Matters

C-A-S-H is a principal binding phase in sustainable cement systems that use supplementary cementitious materials (SCMs) like fly ash or slag. Understanding how its atomic makeup influences mechanical strength, hydration behavior, and defect tolerance is crucial for designing next-generation cements with lower embodied carbon and enhanced performance. This study not only provides the scientific community with a foundational database of validated C-A-S-H structures but also paves the way toward a genetic algorithm approach to materials design.

Looking Ahead: Smarter, Sustainable Cement

The CASHgen tool is open-source and adaptable, meaning its impact could reach beyond cement science into the broader field of nanocrystalline materials research. As machine learning and atomistic simulations increasingly merge, tools like CASHgen represent a vital step in the direction of automated, predictive materials engineering.

As cities continue to grow and infrastructure expands, the need for cleaner, stronger, and smarter cementitious materials becomes ever more urgent. This breakthrough represents a pivotal step toward realizing that vision — proving once again that the path to sustainability runs through the periodic table.

Original research article: High-throughput atomistic modeling of nanocrystalline structure and mechanics of calcium aluminate silicate hydrate, Nature Communications (2025).

Sponsored by PWmat (Lonxun Quantum) – a leading developer of GPU-accelerated materials simulation software for cutting-edge quantum, energy, and semiconductor research. Learn more about our solutions at: https://www.pwmat.com/

📞 Phone: +86 400-618-6006

📧 Email: support@pwmat.com

Comments

Post a Comment