Revolutionizing Glass Fabrication: MIT's Low-Temperature 3D Printing Technique

Published: June 2025

Source: MIT Lincoln Laboratory

Glass is a cornerstone of modern technology—from optical lenses and fiber networks to microfluidics and advanced electronics. Yet, its manufacturing has remained tied to traditional, high-temperature techniques for centuries. Now, researchers at MIT’s Lincoln Laboratory have introduced a low-temperature additive manufacturing method that redefines what’s possible for complex glass structures.

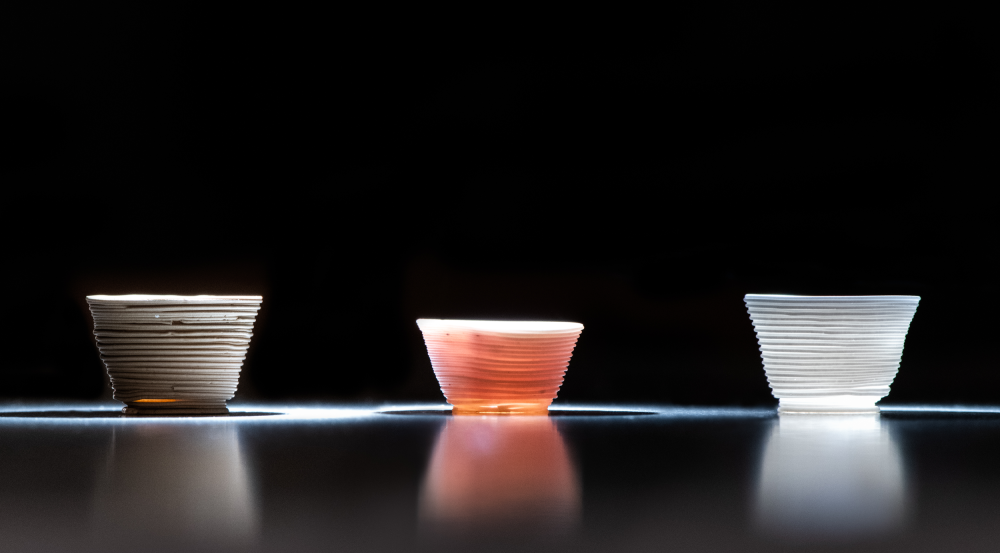

This breakthrough process leverages direct ink writing of custom-engineered silicate-based inks, enabling room-temperature 3D printing of multimaterial glass forms. The printed components are subsequently cured in mineral oil at only 250°C—a dramatic reduction from the >1,000°C temperatures required by conventional sintering methods.

Engineering Glass Inks for Flexibility and Functionality

The innovative ink formulation combines widely available inorganic materials and silicate binders, resulting in high-resolution, thermally stable, and structurally sound components. Once printed, the structures undergo a two-step post-processing phase: heat curing in mineral oil followed by a rinse in organic solvent to remove residues—leaving behind fully inorganic silica-based parts.

This method not only improves energy efficiency but also allows integration with temperature-sensitive components and diverse shapes. As a result, it paves the way for applications in optical components, freeform fiber networks, microfluidic systems, and high-temperature electronics.

Performance Benchmarks and Ongoing Research

Initial tests of this technique revealed promising traits:

- High-resolution print fidelity

- Excellent thermal stability

- Minimal structural shrinkage during curing

Lincoln Laboratory’s team is now focusing on enhancing optical clarity and expanding the range of ink chemistries to introduce tailored chemical and electrical functionalities into printed glass devices.

The Future of Glass Additive Manufacturing

This development represents a transformative leap for microfabrication, photonics, and sensor technologies. By removing the barrier of high-temperature processing, the technique broadens access to rapid prototyping and scalable manufacturing in materials traditionally considered unprintable. It opens entirely new possibilities for smart materials, embedded devices, and next-gen microsystems.

Original article: MIT’s Low-Temperature 3D Printing Process

Sponsored by PWmat (Lonxun Quantum) – a leading developer of GPU-accelerated materials simulation software for cutting-edge quantum, energy, and semiconductor research. Learn more about our solutions at: https://www.pwmat.com/en

📘 Download our latest company brochure to explore our software features, capabilities, and success stories: PWmat PDF Brochure

📞 Phone: +86 400-618-6006

📧 Email: support@pwmat.com

💡 Enjoyed this article? Support independent science reporting — and promote your work!

Quantum Server Networks is a labor of passion, curating and sharing the latest breakthroughs in materials science to inspire researchers, students, and professionals worldwide. If you find value in what I do, consider supporting this work with a small donation. Your support helps keep this blog free, ad-free, and regularly updated with high-quality scientific insights.

👉 Support via PayPal: Donate here

Donors can also feature their own research or scientific work in a dedicated post shared across multiple specialist communities.

📧 To arrange your promotional feature, email: gabriele.mogni@qscomputing.com

Comments

Post a Comment