Revolutionizing 3D Printing: MIT's Light-Switchable Resin for Fast, Sustainable Fabrication

Original article link: MIT News – New 3D printing method enables complex designs, creates less waste

In a major step toward making 3D printing more efficient, customizable, and environmentally friendly, researchers at MIT have unveiled a novel light-sensitive resin that can form either sturdy or dissolvable solids depending on the type of light it’s exposed to. This dual-phase resin could dramatically reduce waste and unlock more intricate printing possibilities by enabling the clean removal and recycling of support structures — a major bottleneck in conventional 3D printing.

🧬 A Smarter Resin for Smarter Prints

Traditional vat photopolymerization (VP), a popular 3D printing method for manufacturing complex items like hearing aids, dental implants, and custom wearables, relies on printing both the desired object and its supporting scaffolding from the same non-recyclable resin. After the object is printed, these support structures must be manually clipped and discarded — often resulting in material waste and added labor.

The MIT team, led by graduate student Nicholas Diaco and professors Robert Macfarlane and A. John Hart, solved this by developing a resin that responds differently to ultraviolet (UV) versus visible light. When exposed to UV light, the resin forms a highly cross-linked, mechanically resilient solid. But under visible light, it solidifies into a loosely bound form that easily dissolves in mild, food-safe solutions — such as baby oil or even the original resin's base liquid.

⚙️ Functional Parts in a Single Run

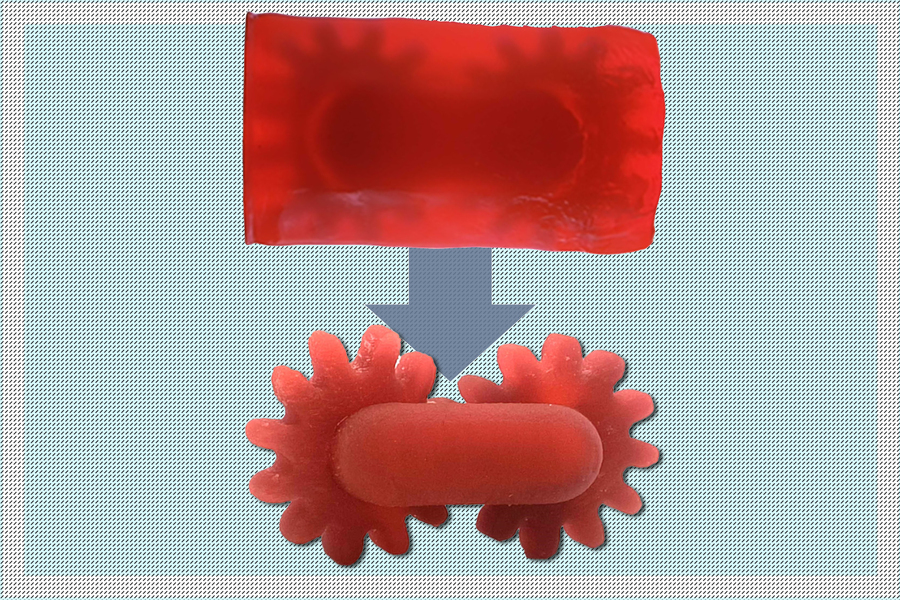

This innovation enables complex structures — like interlocking gears or lattices — to be printed in one go. The sturdy parts form under UV patterns, while the temporary supports are formed simultaneously with visible light. Once printing is complete, a simple solvent bath washes away the supports, revealing a pristine, functional product with no need for manual post-processing.

Even better: the dissolved support material can be recovered and reused in future prints, enabling a closed-loop system that is both cost-effective and environmentally sustainable.

🧪 Chemistry Behind the Breakthrough

The core innovation lies in the molecular design of the resin. The researchers mixed two commercially available monomers that react differently under UV and visible light. They discovered that adding a third bridging monomer enables stronger network formation under UV exposure, making the solid more stable even when printed under less intense LED sources — a critical step for real-world printing setups.

This chemistry makes the process versatile and accessible: the same resin vat can be used to simultaneously create high-strength components and dissolvable supports, using only light as the differentiating input.

🦖 Demonstrations and Applications

To showcase the power of the new method, the team 3D-printed intricate and whimsical objects, including gear trains, a dinosaur encased in a dissolvable egg-like shell, and delicate lattices. They also demonstrated applications in patient-specific products like dental guards, where personalized fit and clean aesthetics are essential.

“This shows we can print multipart assemblies with a lot of moving parts, and detailed, personalized products in a way that’s fast and sustainable,” said Diaco. “Instead of throwing out this material, you can recycle it on site and generate a lot less waste.”

🌍 Toward a Circular Economy in 3D Printing

Professor Hart emphasizes the broader vision: combining wavelength-selective resins with automated handling and closed-loop recycling paves the way for sustainable, industrial-scale additive manufacturing. This approach is poised to benefit industries ranging from biomedical engineering to aerospace and consumer electronics, wherever custom geometries and minimal waste are key.

This project was supported by several major research sponsors, including the U.S. National Science Foundation, the Office of Naval Research, the U.S. Army Research Office, and Hong Kong’s InnoHK initiative.

🔮 The Future of Additive Manufacturing

MIT’s dissolvable support resin is more than a clever trick — it represents a paradigm shift in how we think about material use, customization, and sustainability in manufacturing. As the additive manufacturing sector continues to expand, such innovations could redefine efficiency benchmarks and make 3D printing a truly zero-waste technology.

Expect more to come from this team as they develop new resin chemistries and refine the system for broader commercial adoption.

Read the full article on MIT News.

Keywords: 3D printing, dissolvable resin, vat photopolymerization, additive manufacturing, MIT research, biodegradable supports, digital manufacturing, advanced materials, smart polymers, recyclable resin.

#3DPrinting #AdditiveManufacturing #SustainableTech #MITResearch #PolymerScience #VatPhotopolymerization #SmartMaterials #ResinInnovation #QuantumServerNetworks #MaterialsScience #ClosedLoopManufacturing

Comments

Post a Comment