AI Meets Materials Science: Predicting Coating Degradation with Machine Learning

In a groundbreaking step for predictive maintenance and corrosion science, researchers have developed a sophisticated two-stage machine learning (ML) framework capable of accurately predicting the degradation of protective coatings under diverse environmental conditions. Published in npj Materials Degradation, this approach represents a leap beyond traditional empirical models and paves the way for intelligent infrastructure design and monitoring.

Understanding Coating Behavior in Harsh Environments

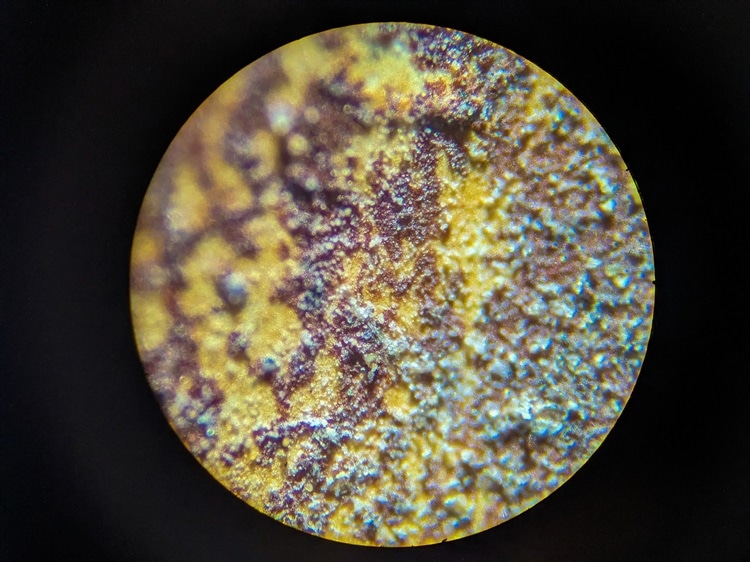

Protective coatings like polyurethane (PU) are widely used to prevent corrosion in sectors such as energy, construction, and maritime transport. However, these coatings gradually degrade due to UV radiation, humidity, heat, and salinity—losing critical properties such as adhesion, gloss, and water contact angle (WCA). Forecasting their performance has been a major challenge due to the complex, non-linear nature of environmental exposure.

This study bridges that gap by integrating real-world environmental data with advanced ML techniques to deliver reliable predictions of corrosion failure—helping engineers and materials scientists anticipate and mitigate damage before it becomes critical.

A Two-Stage Predictive Framework

The researchers implemented a two-tier model. In Stage 1, polyurethane-coated samples were exposed for a year across nine geographically distinct sites including Cairo, Jeddah, Singapore, and Islamabad. These samples were assessed for changes in gloss, adhesion, and WCA.

A semi-supervised co-training regression model called COREG (with feature filtering via Pearson correlation) showed the best predictive performance. Notably, a reduced 4-variable COREG model achieved the lowest root mean square error (RMSE), showing that targeted features yield more accurate and generalizable results.

Stage 2: From Surface Property to Corrosion Forecasting

In the second stage, predicted surface properties were input into another ML layer using support vector regression (SVR), artificial neural networks (ANN), and AdaBoost. Electrochemical impedance spectroscopy (EIS) data served as the corrosion benchmark. A binary classifier also flagged coatings as either damaged or intact.

To further validate the model, accelerated aging experiments were conducted with UV light and salt spray. These tests added 37 new data points and confirmed the model’s accuracy under intensified conditions.

Key Insights and Model Performance

The study yielded several important findings:

- Adhesion was the strongest predictor of corrosion resistance, followed by WCA and gloss, as identified via SHAP (Shapley Additive Explanations) analysis.

- AdaBoost achieved an impressive R² of 0.83 and perfect precision in detecting coating damage.

- Site-specific degradation patterns were observed, with Jeddah samples showing the highest adhesion (6.97 MPa) and Cilacap the lowest (4.03 MPa).

Furthermore, accelerated aging tests confirmed that gloss and impedance are positively correlated, suggesting that surface integrity is a reliable indicator of overall coating health.

Real-World Applications and Future Directions

This intelligent system can assist engineers in proactively managing infrastructure—enabling remote monitoring, predictive maintenance, and better coating selection for harsh environments like coastal or desert regions. It also helps reduce downtime and improve safety by flagging early signs of degradation.

Looking forward, the authors suggest expanding the dataset to include variables like air pollutants and mechanical stress, and incorporating real-time sensor data to enhance the system’s learning capabilities. These improvements could drive the development of smart coatings that are self-monitoring, adaptive, and even self-healing.

Conclusion: A Smarter Path to Corrosion Resistance

By uniting machine learning with material degradation science, this study provides a practical, data-driven solution for optimizing coating performance and preventing infrastructure decay. It’s a compelling example of how AI can extend the life of materials and support the shift toward sustainable engineering.

📖 Read the original article on AZoM:

https://www.azom.com/news.aspx?newsID=64684

Sponsored by PWmat (Lonxun Quantum) – a leading developer of GPU-accelerated materials simulation software for cutting-edge quantum, energy, and semiconductor research. Learn more about our solutions at: https://www.pwmat.com/en

📘 Download our latest company brochure to explore our software features, capabilities, and success stories: PWmat PDF Brochure

📞 Phone: +86 400-618-6006

📧 Email: support@pwmat.com

#CoatingDegradation #MachineLearningMaterials #PredictiveMaintenance #SmartCoatings #CorrosionResistance #MaterialsScience #DataDrivenDesign #AdaBoost #AIForEngineering #PWmat #QuantumServerNetworks

Comments

Post a Comment