How Rolling Particles Are Revolutionizing the Science of Suspensions

In a world where concrete, ketchup, and paint behave more like puzzles than fluids, a team of brilliant minds at ETH Zurich has taken materials science to a thrilling new level. Led by Professor Lucio Isa, researchers have for the first time measured the microscopic forces that govern how tiny particles roll past each other in dense suspensions. The implications? Game-changing innovations for industries as diverse as construction and microelectronics.

The Hidden Life of Suspensions

From your kitchen shelf to industrial production lines, suspensions are everywhere. These are liquids that carry tiny solid particles—think of concrete, lacquers, orange juice, or even solder paste. But there's a twist: the moment you apply pressure or force, these liquids can thicken and suddenly act like solids. Welcome to the world of non-Newtonian fluids.

This unexpected thickening is due to the interaction between the particles. When they roll smoothly past each other, the fluid remains runny. But when they jam or slide, viscosity skyrockets. To understand and optimize these behaviors, scientists must look at what happens on the microscale.

Atomic-Level Insights

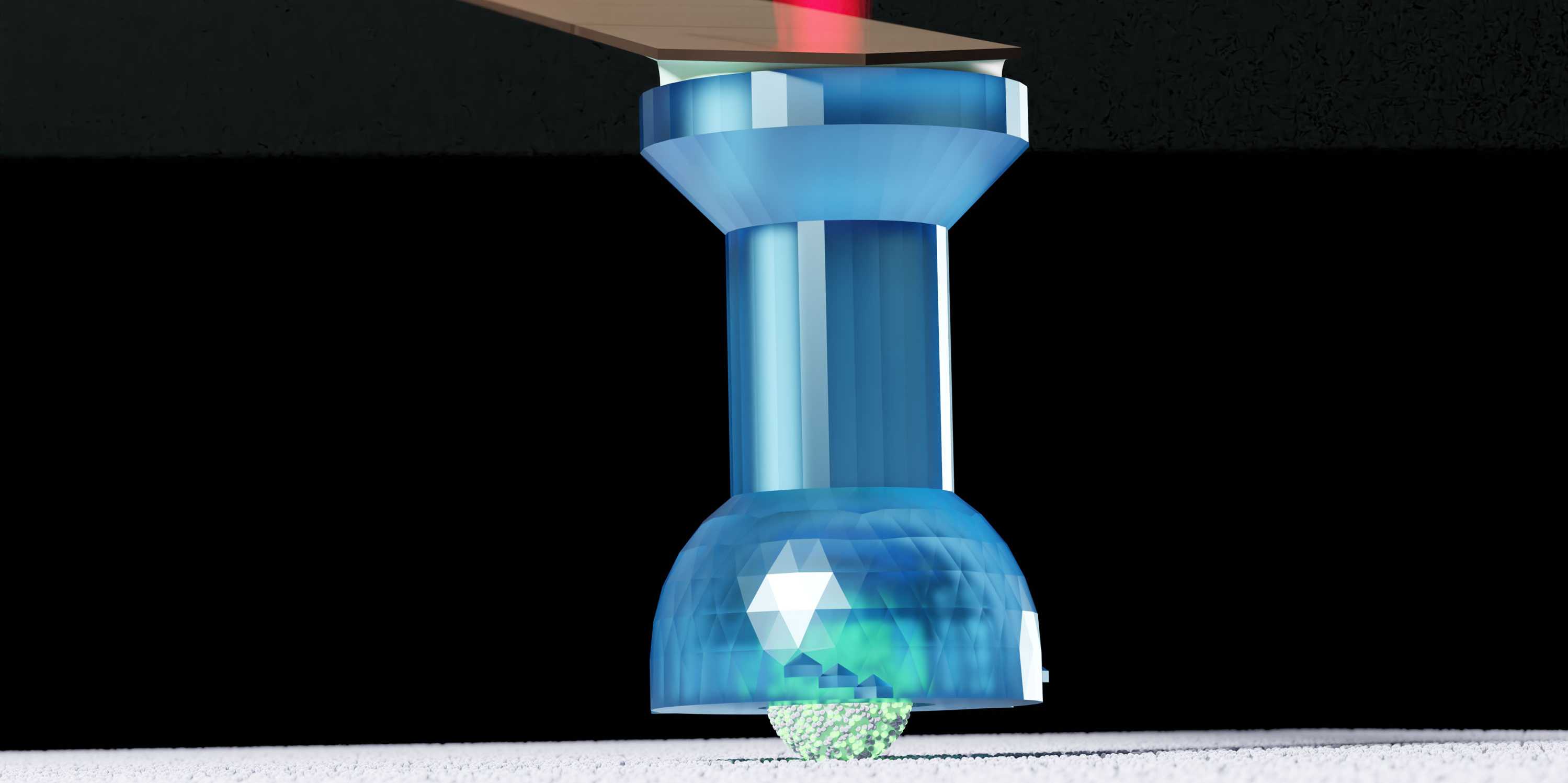

Using a customized atomic force microscope, doctoral researcher Simon Scherrer developed an innovative holder to "trap" single spherical particles just 12 micrometres in diameter. Moving these particles over similar surfaces allowed the team to simulate and measure both rolling and sliding friction.

The findings were eye-opening. Smooth particles glided effortlessly, while rough or sticky particles engaged like tiny gears, rolling with ease but resisting slides. This distinction helps explain why some suspensions behave erratically under pressure—knowledge that is vital for avoiding clogged nozzles or inconsistent flow in high-tech manufacturing processes.

Why This Research Matters

The ETH Zurich team derived precise friction coefficients from their measurements and integrated them into computer models that simulate suspension behavior. These models can now help industries tailor flow properties for specific applications—from optimizing concrete mixtures to improving the performance of conductive pastes in microelectronics.

“In order to prevent this behavior and optimize such suspensions, we have to know precisely how particles behave on a microscale and what forces occur in the process,” explains Professor Isa.

The research is already being recognized as a cornerstone in the design of smarter, more adaptable materials.

Further Reading

Originally published by ETH Zurich on April 7, 2025. Read the full article here: Rolling particles make suspensions more fluid

Research publication reference: Scherrer et al., "Characterizing sliding and rolling contacts between single particles," Proceedings of the National Academy of Sciences, March 2025, DOI: 10.1073/pnas.2411414122

© 2025 Quantum Server Networks – Exploring the Frontiers of Materials Science and Nanotech

Comments

Post a Comment